Peter

Active member

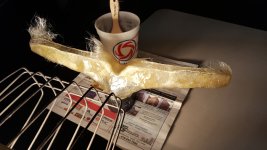

Had the same problem, I use a phylum box for 2 1/2" 63mm ducting (and two 1 1/4" demist) but after making a pair of flaps and all the levers, cables knobs etc I binned it all and went for bulls eye vents I could open and close individually and also redirect to the screen. Lucky I don't need to worry about heating.

Eyeball Dash Vent Chrome - Car Builder Solutions - Kit Car Parts and Accessories

Eyeball Dash Vent Chrome - Car Builder Solutions - Kit Car Parts and Accessories

Last edited: