Zenny

Member

I decided it's finally time to make my own Builders Journal here, especially since I've made some progress. I'm not sure how much I'll post about what I've done so far, but I plan on making posts at every major point in the future.

For starters, here's the beginning.

It's a subpar picture, but that's what it looked like. You can see that it has taken a bit of damage and is missing a lot, but at least I have this much.

I'll get pictures later since it seems I haven't taken any, but I do actually have a rear window as well. The plastic shroud that surrounds it and walls off the inside of the body is utterly trashed but the glass is intact.

I have the (assumed) original gauge cluster, wiper motor, hood, lights, and rear bumper as well, so that's a plus. I fully intend on keeping this, with my only current plans being to replace the mounting surface and retouch the exterior with paint.

The first thing I recall getting around to removing was the door, which came off on the 23rd of November, 2 days after I got it to my friend's yard. From there we got around to cleaning up the interior, but that was just another detour from the correct path of removing the body. I think it's probably self explanatory what the before and after is.

^ Here you can see the horrendous floorpan drop attempt from the previous owner, the pieces of metal were lazily shoved on top of eachother and poorly bent, and the only method of attachment was 6 screws along the rear perimeter and metric tonnes of caulking.

I was still taking classes at this point in time so I didn't have much time to work on the Sterling. This plus my lacking discipline and motivation levels made this disassembly take quite a while, but with the help of 2 friends and a month's time, the body did get removed.

(11/26/2021)

I think I've typed enough for now, and this just about catches up to where the car is currently. As of now, it is nearly completely bare (All that's left is to remove the 2 ebrake lines and cut off 2 welded brake line mounts). Once it is bare, the plan is to finish assaulting the frame with wire wheels, cut the underside of the center tunnel, clean and de-rust it, close and weld the bottom back on, and then spraypaint it to protect it from future rust.

Key things about this car:

I've read over the builders manual a few times and after comparing directions to the actual product here, it seems like the original builder cut a lot of corners and didn't do some things at all.

After looking in the front wheel wells, it seems that there is fiberglass repair at the top of the arch, and it is clearly visible on the exterior (see second picture in post). I am under the impression that this car was involved in some kind of front end impact and it has been half repaired.

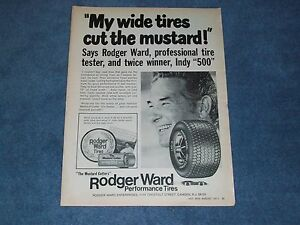

I really hope the tires on this car are not the original ones, but the time periods do overlap enough to be believable. 3/4 wheels are those solid steel beauties visible in the first and second pictures, and the passenger front wheel is some random swap from some other car. The tires on the 3 steelies are Rodger Ward Indy Champ "Mustard Cutters" according to the incredibly limited info I can find on them. They were probably manufactured in 1972 (below is a magazine picture I was able to find), which is only 4 years before this particular body was made. Judging by the ~2mm of tread left, these guys were pretty heavily used. Does that mean they were on this sterling when it was still driven around? Maybe, but it could be a bit of supporting evidence for my theory of this car being in a crash at some point, and then being sold around as a parts car through the years.

For starters, here's the beginning.

It's a subpar picture, but that's what it looked like. You can see that it has taken a bit of damage and is missing a lot, but at least I have this much.

I'll get pictures later since it seems I haven't taken any, but I do actually have a rear window as well. The plastic shroud that surrounds it and walls off the inside of the body is utterly trashed but the glass is intact.

I have the (assumed) original gauge cluster, wiper motor, hood, lights, and rear bumper as well, so that's a plus. I fully intend on keeping this, with my only current plans being to replace the mounting surface and retouch the exterior with paint.

The first thing I recall getting around to removing was the door, which came off on the 23rd of November, 2 days after I got it to my friend's yard. From there we got around to cleaning up the interior, but that was just another detour from the correct path of removing the body. I think it's probably self explanatory what the before and after is.

^ Here you can see the horrendous floorpan drop attempt from the previous owner, the pieces of metal were lazily shoved on top of eachother and poorly bent, and the only method of attachment was 6 screws along the rear perimeter and metric tonnes of caulking.

I was still taking classes at this point in time so I didn't have much time to work on the Sterling. This plus my lacking discipline and motivation levels made this disassembly take quite a while, but with the help of 2 friends and a month's time, the body did get removed.

(11/26/2021)

I think I've typed enough for now, and this just about catches up to where the car is currently. As of now, it is nearly completely bare (All that's left is to remove the 2 ebrake lines and cut off 2 welded brake line mounts). Once it is bare, the plan is to finish assaulting the frame with wire wheels, cut the underside of the center tunnel, clean and de-rust it, close and weld the bottom back on, and then spraypaint it to protect it from future rust.

Key things about this car:

I've read over the builders manual a few times and after comparing directions to the actual product here, it seems like the original builder cut a lot of corners and didn't do some things at all.

After looking in the front wheel wells, it seems that there is fiberglass repair at the top of the arch, and it is clearly visible on the exterior (see second picture in post). I am under the impression that this car was involved in some kind of front end impact and it has been half repaired.

I really hope the tires on this car are not the original ones, but the time periods do overlap enough to be believable. 3/4 wheels are those solid steel beauties visible in the first and second pictures, and the passenger front wheel is some random swap from some other car. The tires on the 3 steelies are Rodger Ward Indy Champ "Mustard Cutters" according to the incredibly limited info I can find on them. They were probably manufactured in 1972 (below is a magazine picture I was able to find), which is only 4 years before this particular body was made. Judging by the ~2mm of tread left, these guys were pretty heavily used. Does that mean they were on this sterling when it was still driven around? Maybe, but it could be a bit of supporting evidence for my theory of this car being in a crash at some point, and then being sold around as a parts car through the years.